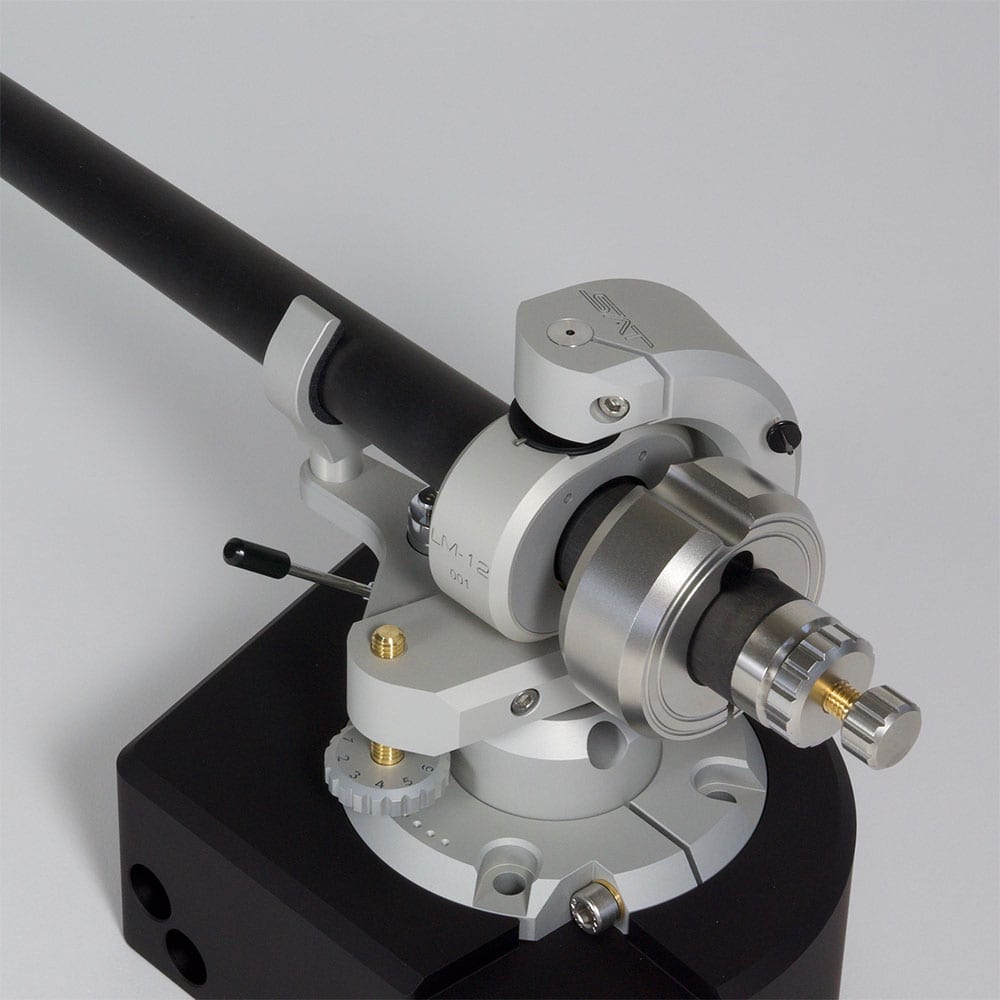

CF1-12Ti

SAT 12-INCH GEOMETRY

- Mounting distance: 280,0mm

- Overhang: 17,6mm

- Offset angle: 20,3°

- Innermost groove radius: 75mm

- Outermost groove radius: 143mm

- Nominal linear offset: 103,4mm

CF1-Ti Pickup Arms

- Arm Tube: Carbon-fiber with internal titanium tube for increased mass/stiffness, higher-grade carbon fiber and larger diameter than LM Series, more advanced CNC machine patterning.

- Headshell: Hybrid carbon-fiber/titanium with titanium frame. Detachable with azimuth adjustment.

- Vertical Bearings: High stiffness, no-stiction, pre-loaded & sealed. Proprietary design. Maintenance-free.

- Horizontal Bearing: Tungsten carbide point on sapphire jewel. Pre-load adjustment.

- Height Adjustment: Via knurled dial with 0.1mm divisions. On-the-fly adjustment.

- Counterweight: Stainless steel, thicker and more robust fine counterweight thread post.

- Main and Secondary Yokes: Stainless steel, thicker than LM Series. Cardanic arrangement.

- Arm Base: Aluminum alloy with clamping device.

- Main Pillar: Stainless steel

- Skating Compensation: Constant torque via weight & low friction pulleys.

The ultimate goal of a pickup arm is to provide a stable platform for the cartridge, so that all of the information in the LP groove is transcribed as perfectly as possible. The perfect pickup arm and record player system would be so stiff it would only allow the movement of the generator in the cartridge.

SAT’s CF1 Series defines the current state-of-the-art in pickup arm design and manufacture. It is the culmination of years of meticulous study of design and materials application by SAT Chief and Engineer Marc Gomez.

SAT’s LM Series pickup arms are so radically superior it’s fair to wonder how they could be improved upon. Indeed the elemental design of the CF1 Series 9” and 12” arms is similar, but with CF1 no expense is spared in production or materials selection in achieving the ultimate in stiffness and fidelity to the source.

All of SAT’s carbon-fiber components are designed in-house and built from the ground up using aerospace industry grades of carbon-fiber rather than common off-the-shelf materials and processes. Each SAT arm tube and headshell is hand-laminated using proprietary processes enabling SAT’s pickup arms to achieve levels of performance not possible any other way.

While tungsten carbide-sapphire bearings of differing stiffness are shared among SAT’s pickup arms, the horizontal and vertical bearing yokes in CF1-09 and CF1-12 are upgraded to stainless steel and are more substantial, offering better damping and rigidity. CF1 arm tubes are also larger for increased stiffness and comprised of more complex layers of higher-grade carbon-fiber.

The CF1-Ti arms are even more extreme. There is even more involved in the machining of the carbon-fiber arm tube, and per the “Ti” designation the arm tube contains an inner titanium tube for increased mass, higher damping and even greater rigidity. Where the CF1 arms employ a hybrid carbon-fiber/aluminum headshell, the CF1-Ti headshell is carbon-fiber/titanium with a titanium frame.The counterweight is stainless steel and uses an internal tungsten weight system.